Адрес:149, Aimin Road, Chashan Town, Dongguan, Guangdong, China

Телефон:1388xx888xx

Мобильные телефоны:1388xx888xx

Почтовый ящик:1388xx888xx@gmail.com

В современном мире производства, где конкуренция растет с каждым днем, а требования к качеству и эффективности становятся все более жесткими, инновационные технологии играют ключевую роль. Одним из таких прорывных элементов являются алюминиевые профильные прессформы, которые кардинально изменили ландшафт промышленного производства. Эти инструменты не просто улучшили процессы; они совершили настоящую революцию, позволив компаниям достигать беспрецедентных уровней точности, скорости и экономии ресурсов. В этой статье мы глубоко погрузимся в мир алюминиевых прессформ, исследуя их историю, преимущества, технологические инновации, применение в различных отраслях, а также будущие тенденции, которые продолжат формировать промышленность.

Введение в алюминиевые прессформы и их значение

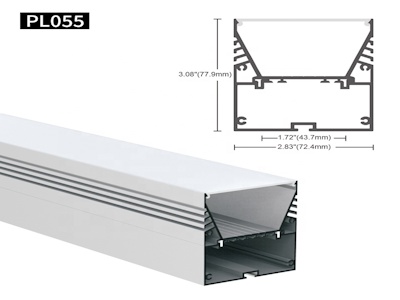

Алюминиевые прессформы — это специализированные инструменты, используемые в процессе экструзии алюминия для создания профилей различных форм и размеров. Экструзия — это метод, при котором алюминиевый сплав пропускается через прессформу под высоким давлением, resulting in the desired cross-sectional shape. Этот процесс широко применяется в таких отраслях, как строительство, automotive, aerospace, and consumer goods, due to aluminum's lightweight, corrosion-resistant, and recyclable properties.

История алюминиевых прессформ восходит к началу 20 века, когда экструзия стала коммерчески viable. Initially, прессформы изготавливались из стали, но с advancements in materials science, aluminum alloys were introduced for the dies themselves, offering benefits like faster heat dissipation and reduced weight. The innovation didn't stop there; modern aluminum press dies incorporate computer-aided design (CAD), finite element analysis (FEA), and additive manufacturing, making them more precise and efficient than ever before.

Значение этих прессформ невозможно переоценить. Они enable mass production of complex profiles with tight tolerances, reduce material waste, and lower energy consumption. For instance, in the construction industry, aluminum profiles are used for window frames, curtain walls, and structural components, where precision is critical for assembly and performance. The automotive sector relies on them for lightweight parts that improve fuel efficiency and reduce emissions. This revolution in production has not only boosted productivity but also contributed to sustainability efforts by promoting recycling and energy efficiency.

Преимущества инновационных алюминиевых прессформ

Инновационные алюминиевые прессформы offer a multitude of advantages over traditional steel dies or older aluminum designs. These benefits stem from advancements in materials, design software, and manufacturing techniques.

First and foremost, алюминиевые прессформы excel in thermal management. Aluminum has a high thermal conductivity, which allows for rapid heat dissipation during the extrusion process. This reduces the risk of overheating, extends the die's lifespan, and improves the quality of the extruded profiles by minimizing defects like warping or cracking. In contrast, steel dies retain heat longer, leading to slower cycle times and potential quality issues.

Another key advantage is weight reduction. Aluminum dies are significantly lighter than their steel counterparts, making them easier to handle, install, and maintain. This reduces labor costs and downtime in production facilities. Additionally, the lighter weight contributes to energy savings during operation, as less force is required to move and press the dies.

Precision and complexity are also enhanced with innovative aluminum press dies. With CAD and FEA, designers can create intricate profiles with micron-level accuracy. This allows for the production of custom shapes that were previously impossible or too expensive to manufacture. For example, in the electronics industry, aluminum profiles are used for heat sinks and enclosures that require precise dimensions for optimal performance.

Cost-effectiveness is a major driver for adoption. While initial investment in high-quality aluminum dies might be higher than for steel, the long-term savings are substantial. Aluminum dies have a longer service life due to better wear resistance and easier repairability. They also reduce scrap rates by producing more consistent profiles, which translates to lower material costs and less waste.

Environmental benefits cannot be overlooked. Aluminum is highly recyclable, and using aluminum dies aligns with circular economy principles. The extrusion process itself is energy-efficient, especially when combined with modern presses that recover and reuse energy. This makes aluminum press dies a sustainable choice for forward-thinking companies.

In summary, the advantages of innovative aluminum press dies include improved thermal performance, reduced weight, enhanced precision, cost savings, and environmental sustainability. These factors collectively contribute to a revolution in production, enabling industries to meet evolving demands for quality, efficiency, and eco-friendliness.

Технологические инновации в алюминиевых прессформах

Технологический прогресс has been the cornerstone of the revolution in aluminum press dies. Several key innovations have transformed these tools from simple metal shapes into sophisticated, high-performance assets.

Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) have revolutionized die design. With CAD software, engineers can create detailed 3D models of press dies, simulating the extrusion process to optimize flow, pressure, and temperature distribution. This virtual prototyping reduces the need for physical trials, saving time and resources. CAM systems then translate these designs into precise machining instructions for CNC (Computer Numerical Control) machines, ensuring that the dies are manufactured with exceptional accuracy.

Finite Element Analysis (FEA) is another critical innovation. FEA software allows engineers to analyze stresses, strains, and thermal effects on the die during extrusion. By identifying potential failure points or inefficiencies, designers can make adjustments to improve durability and performance. For instance, FEA can help optimize the die's geometry to minimize material usage while maintaining structural integrity.

Additive manufacturing, or 3D printing, has emerged as a game-changer for producing complex press dies. Techniques like selective laser melting (SLM) enable the creation of dies with internal cooling channels or intricate features that are difficult to achieve with traditional machining. This not only enhances cooling efficiency but also allows for rapid prototyping and customization. Companies can now produce bespoke dies in days rather than weeks, accelerating time-to-market for new products.

Surface treatment technologies have also advanced significantly. Coatings such as titanium nitride (TiN) or diamond-like carbon (DLC) are applied to aluminum dies to increase hardness, reduce friction, and extend lifespan. These treatments make the dies more resistant to wear and corrosion, which is crucial for high-volume production environments.

Integration with Industry 4.0 and IoT (Internet of Things) is the latest frontier. Smart press dies equipped with sensors can monitor parameters like temperature, pressure, and wear in real-time. Data collected from these sensors is analyzed using AI algorithms to predict maintenance needs, optimize production schedules, and prevent downtime. This predictive maintenance approach ensures that dies are serviced before failures occur, maximizing uptime and efficiency.

Furthermore, advancements in material science have led to the development of new aluminum alloys with improved properties. Alloys with higher strength-to-weight ratios, better thermal stability, and enhanced corrosion resistance are now available, making press dies more robust and versatile.

These technological innovations collectively enhance the performance, reliability, and adaptability of aluminum press dies. They enable producers to tackle more challenging projects, reduce costs, and stay competitive in a fast-paced market. The continuous evolution of technology promises even greater breakthroughs in the future, such as AI-driven design optimization and fully automated die production.

Применение алюминиевых прессформ в различных отраслях

Алюминиевые прессформы нашли widespread application across numerous industries, thanks to their versatility and performance benefits. Each sector leverages these tools to address specific challenges and opportunities.

In the construction industry, aluminum profiles are essential for modern building techniques. Press dies are used to produce window and door frames, curtain wall systems, and structural components. The precision of innovative dies ensures that profiles fit perfectly during assembly, reducing installation time and improving energy efficiency through better insulation. For example, in skyscrapers, aluminum profiles contribute to lightweight yet strong facades that withstand environmental stresses.

The automotive industry heavily relies on aluminum press dies for lightweighting initiatives. As manufacturers strive to meet stringent emissions regulations, aluminum parts replace heavier steel components in vehicles. Press dies produce profiles for chassis, body panels, and interior parts, enhancing fuel efficiency without compromising safety. The ability to create complex shapes allows for aerodynamic designs that reduce drag and improve performance.

In aerospace, where weight savings are critical, aluminum press dies are used to manufacture components for aircraft and spacecraft. Profiles for fuselage sections, wing structures, and interior fittings are extruded with high precision to meet rigorous standards. The thermal management properties of aluminum dies ensure consistent quality even under extreme conditions, such as during high-speed飞行.

The electronics industry benefits from aluminum profiles for heat dissipation and enclosure applications. Press dies produce heat sinks that efficiently cool processors and other components, preventing overheating and extending device lifespan. The miniaturization trend in electronics demands ever-smaller and more intricate profiles, which innovative dies can deliver with accuracy.

Consumer goods, such as furniture and appliances, also utilize aluminum press dies. Profiles for shelving, frames, and handles are produced cost-effectively, offering durability and aesthetic appeal. The flexibility of aluminum allows for custom designs that cater to consumer preferences, from minimalist styles to ornate patterns.

Renewable energy sectors, like solar and wind power, employ aluminum profiles for mounting systems and structural supports. Press dies enable the production of robust, corrosion-resistant components that endure harsh outdoor environments. This supports the growth of sustainable energy infrastructure worldwide.

Additionally, the medical industry uses aluminum profiles for equipment frames, surgical tools, and diagnostic devices. The non-toxic and easy-to-clean properties of aluminum make it ideal for healthcare settings, while precision extrusion ensures reliability and safety.

In each of these industries, innovative aluminum press dies facilitate innovation, efficiency, and sustainability. They empower companies to create products that are lighter, stronger, and more environmentally friendly, driving progress across the global economy.

Будущие тенденции и развитие алюминиевых прессформ

Будущее алюминиевых прессформ looks promising, with several trends set to shape their evolution and further revolutionize production.

Artificial Intelligence (AI) and Machine Learning will play an increasingly important role. AI algorithms can analyze vast amounts of data from extrusion processes to optimize die design and operation in real-time. For example, AI can predict wear patterns and suggest adjustments to prolong die life, or automatically calibrate press parameters for different materials, reducing human error and enhancing consistency.

Sustainability will continue to be a driving force. As circular economy principles gain traction, there will be a greater emphasis on designing press dies for easy disassembly and recycling. Advances in bio-based or recycled aluminum alloys could reduce the environmental footprint further. Additionally, energy-efficient extrusion presses coupled with smart dies will minimize carbon emissions, aligning with global sustainability goals.

Additive manufacturing will become more prevalent, enabling the production of press dies with unprecedented complexity. 3D printing could allow for on-demand die manufacturing near production sites, reducing logistics costs and lead times. This democratization of die production might empower smaller companies to compete with industry giants.

Customization and personalization will rise, driven by consumer demand for unique products. Press dies will be designed to quickly switch between profiles, supporting small-batch production runs without significant downtime. This flexibility will be crucial for industries like fashion or automotive, where trends change rapidly.

Integration with digital twins—virtual replicas of physical dies—will enhance monitoring and maintenance. Digital twins can simulate extrusion processes under various conditions, allowing for proactive optimization and trouble-shooting before issues arise in the real world. This will reduce downtime and improve overall equipment effectiveness (OEE).

New materials and composites might emerge, blending aluminum with other substances to create dies with superior properties. For instance, nanocomposites could offer enhanced strength and thermal conductivity, pushing the boundaries of what's possible in extrusion.

Global collaboration and standardization will facilitate knowledge sharing and innovation. International standards for die design and manufacturing could streamline processes and ensure quality across borders, fostering a more interconnected and efficient global supply chain.

In conclusion, the future of aluminum press dies is bright, with technology and sustainability at its core. These trends will not only enhance performance but also make production more adaptive, resilient, and environmentally responsible. Companies that embrace these advancements will lead the next wave of industrial revolution.

Заключение: Революция, которая продолжается

Инновационные алюминиевые профильные прессформы undeniably represent a revolution in production. From their humble beginnings to today's high-tech tools, they have transformed industries by enabling precision, efficiency, and sustainability. The advantages of improved thermal management, reduced weight, and cost savings, coupled with technological innovations like CAD, FEA, and additive manufacturing, have made them indispensable in modern manufacturing.

Their application across construction, automotive, aerospace, electronics, and other sectors demonstrates their versatility and impact. As we look to the future, trends such as AI integration, sustainability focus, and advanced materials promise to further elevate their role. This ongoing evolution ensures that aluminum press dies will continue to drive progress, helping businesses meet the challenges of tomorrow while reducing their environmental footprint.

Embracing these innovations is not just an option but a necessity for companies aiming to stay competitive. By investing in state-of-the-art press dies, producers can unlock new levels of productivity and creativity, ultimately contributing to a smarter, greener, and more prosperous world. The revolution in production is here, and it is powered by aluminum.

1388xx888xx

1388xx888xx